When the time comes to chose between a tube or a hose for your hydraulic needs, there’s a lot to take into account. You need to ask yourself some questions in order to pick the correct solution for your needs. For example:

- When would you use a metal tube over a hose?

- When would you pick a hose over a metal tube?

- Is it even possible to replace a metal tube assembly with a hose? If so, should you do so?

Both options have their good and bad points dependent on the application they’re to be used for. A piece of hydraulic equipment can have both fittings in different parts of the system. Generally speaking, tubes are best used near heat sources whereas a hose is best used if it’s to be attached to any moving parts for instances, where high vibration is present. If you’re still in two minds in terms of weighing up the benefits of each, take a look:

Benefits of Using Tube

Some of the benefits of tube include:

- Generally not as heavy as hose

- Consistent dimensions even under pressure

- Higher dissipation of heat

Drawbacks of Using Tube

some major drawbacks of using tube include:

- Only useful in rigid applications

- Maximum length of 20 feet

- Corrodes easily

- Transfers any vibration to other components

- Bad heat insulation

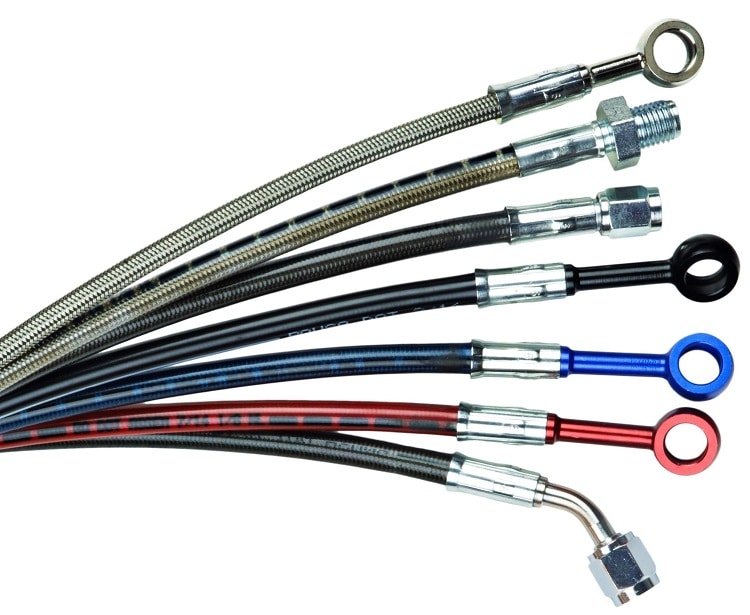

Benefits of Hose

If you’re considering using hydraulic hose, bear in mind the following:

- Generally less likely to corrode

- Good heat insulation

- Flexible enough to be used in dynamic applications

- Longer lengths than tube available

- Easily installed in hard-to-reach places

- No transfer of noise and vibration

Drawbacks of Hose

Hose tends to be a good choice for many applications, but, as with everything, there are some drawbacks.

- Limited temperature range for operating

- Heavier

- Tends not to dissipate heat well

- Fittings can corrode

If you’re looking for more information on hydraulic hoses or are looking for hydraulic hose repair, Perth-based company Hoseright can help. Contact us today on 08 9409 7375.